Fact checking of shock absorber myths

Do twin-tube dampers need to be “pumped” before installation? Will the air-suspension bellows break when lifting vehicles if the engine is running at the same time? What helps against the notorious “morning sickness”? A lot of unclear information is circulating around the topic of suspensions. The manufacturer BILSTEIN is therefore doing a fact check on half a dozen of the most popular myths.

Myth 1: Do twin-tube dampers need to be “pumped” before installation to vent them?

This is a misconception! The fact is: twin-tube shock absorbers are installed in vertical position or up to a maximum of 45° inclination, but stored horizontally at the dealership. However, this “change of position” has no relevance for the installation. If there is still not enough oil in the inner tube/working tube after installation, it sucks in the required oil itself later when “working”.

Myth 2: How about the “morning sickness” with shock absorbers?

The phenomenon of the so-called “morning sickness” with twin-tube shock absorbers is based on the fact that the shock absorber oil cools down overnight, thereby reducing its volume. As a result, it contracts, so that in the end there may be too little oil in the inner tube. The movement of the piston rod / working piston, however, quickly sucks oil in for replenishment. If the oil warms up, the volume also increases again quickly.

Not really a myth, but an often misunderstood feature, is the groove adjustment found on many shock absorbers. Find out more about this on REPEXPERT.

Myth 3: Lifting of vehicles with air suspension

It is a popular theory that when vehicles are lifted with the engine running, the air-suspension bellows are pressurised until they burst. At least if the workshop mode has not been activated. It is correct that in the case described, air is rather let out. Thus, strangely enough, the opposite problem rather occurs: there is a risk that the vehicle could be lowered onto an unpressurised or at least partially deflated air spring which can be damaged as a result.

For all those who would like to know more about air suspension systems, BILSTEIN has produced an interesting training video, showing the installation of a BILSTEIN B4 air suspension module is also interesting:

Installation instruction – Mercedes-Benz C-Class W205 front axle – BILSTEIN B4 Air Suspension Module

This video shows what to bear in mind when installing air springs separately from the damper.

Myth 4: Checking the radial clearance on the piston rod

When checking the suspension, this scene is still widespread: The mechanic checks the lateral play on the newly installed – or even old – shock absorber at the extended piston rod. This is not a good idea, because there is an extremely long lever arm here, and thus poor support of the piston rod is guaranteed. This method almost inevitably diagnoses excessive radial play. In order to correctly determine any radial play that may exist, the piston rod/working piston must be in the design position of the vehicle/suspension. It should be noted, however, that no standardised guide values exist.

It is often also difficult to identify the cause of disturbing noises from the suspension. The article linked here on REPXPERT explains how workshops can proceed sensibly.

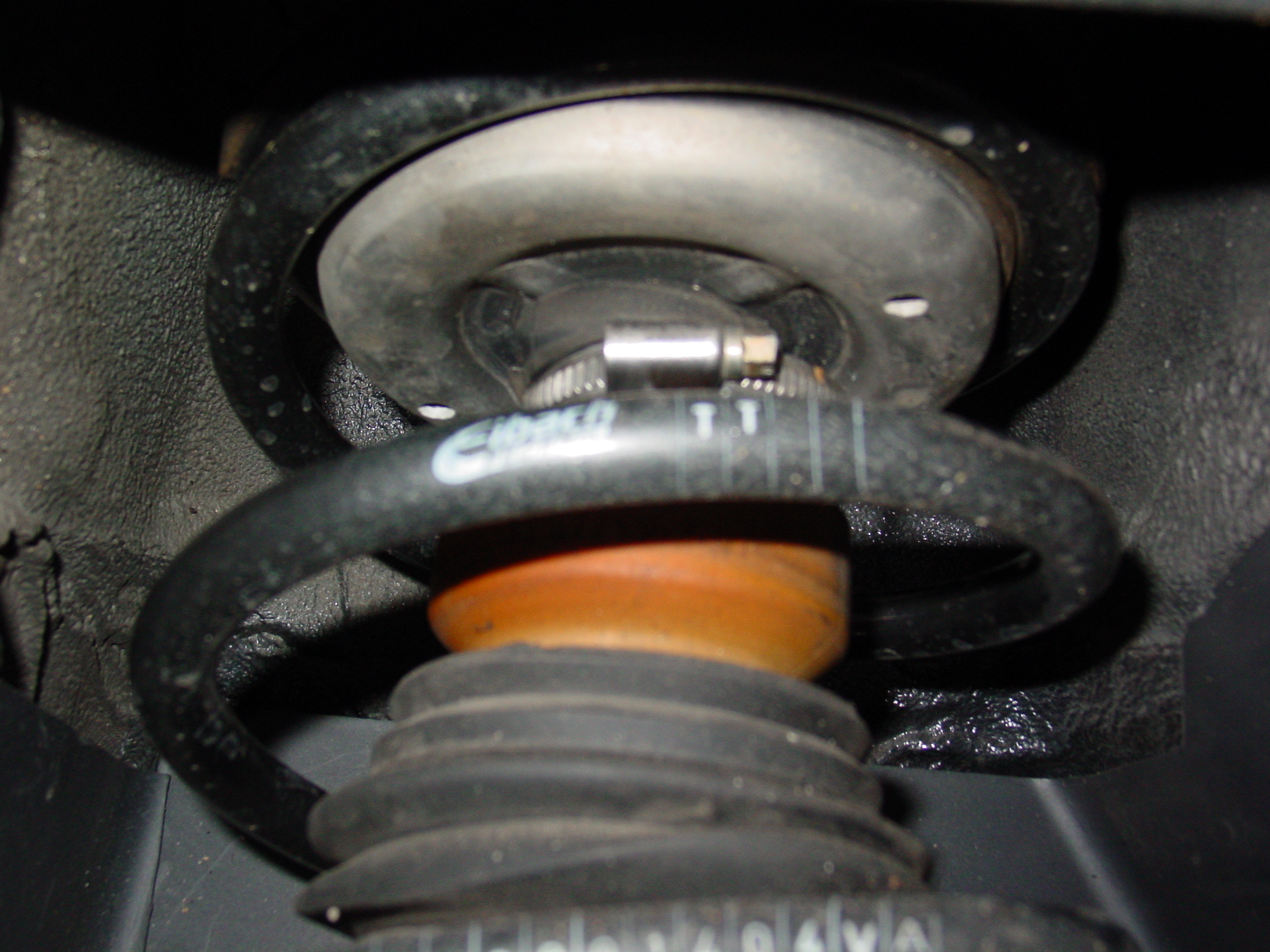

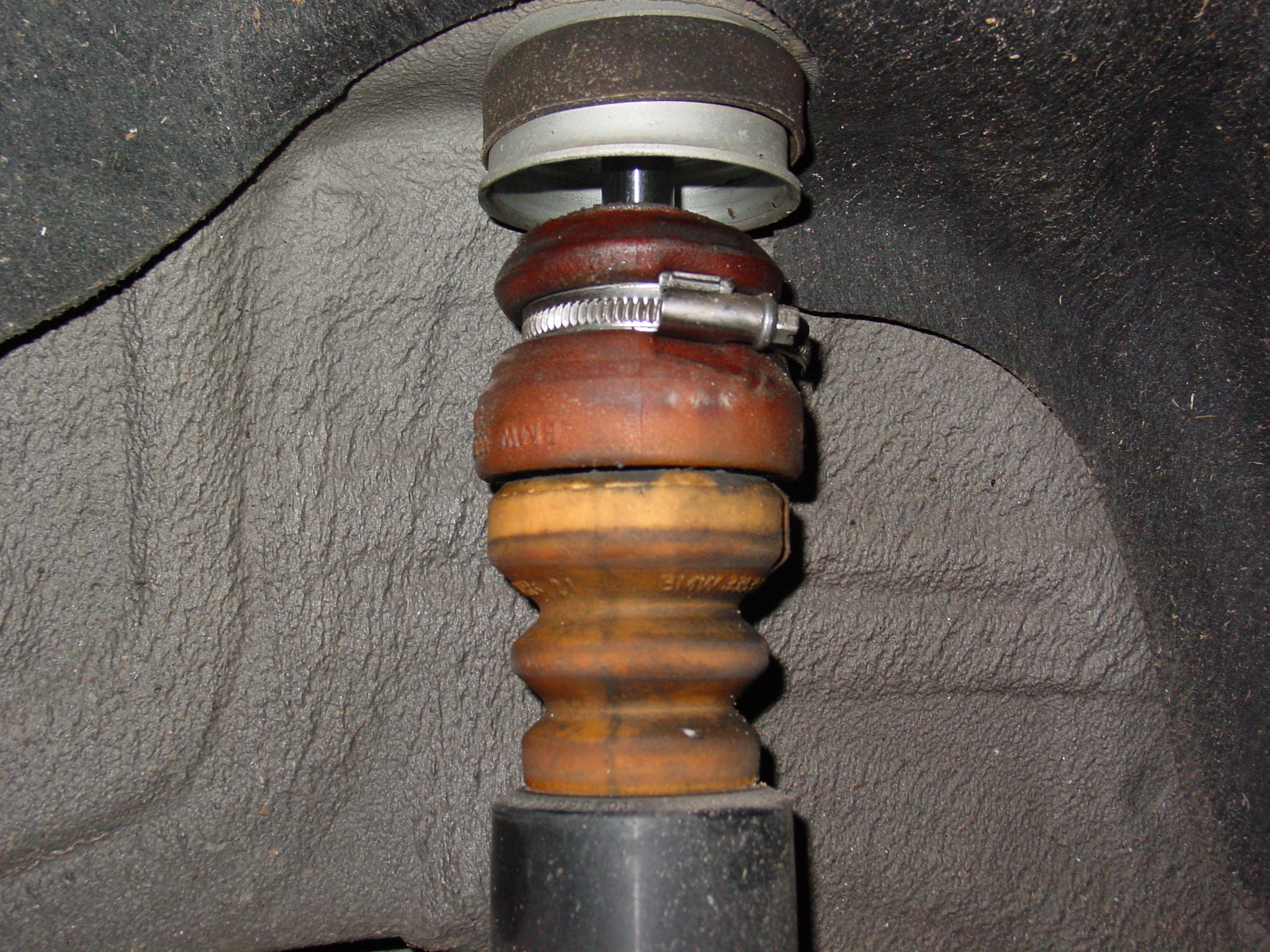

Myth 5: Bump stops

Bump stops are also much discussed, but this does not refer to the existing pressure stops/buffers, but rather to components for retrofitting. It is often incorrectly claimed that these protect the suspension and car body during the compression process. However, bump stops take away the necessary spring travel from the vehicle. They prevent the shock absorber from sensibly reducing the dynamic vibrations from the suspension. Thus, the opposite of the initial statement is true: Suspension parts and bodywork tend to be overstressed by the bump stops. In addition, the handling is hard and bumpy.

Myth 6: Harder suspensions improve driving dynamics

It is a popular opinion that the harder the suspension is, the more it feels like driving a sports car. The fact is: even a sports suspension must be balanced. Extremes are often counterproductive. It is correct that lowering of the vehicle’s centre of gravity, which must be precisely defined, reduces the tendency to roll and improves the driving dynamics with the maximum possible residual spring travel. When using sports springs, preferably in conjunction with suitable high-performance shock absorbers, a technically reasonable measure must always be taken into account: e.g., 40mm lower means 40mm less spring deflection travel at the axle. Sufficient residual spring travel should, however, always remain available. Therefore, BILSTEIN always pays attention to optimal drivability with its performance products.