Your checklist.

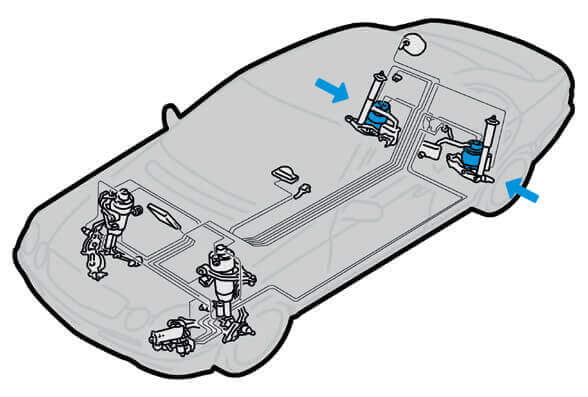

What absolutely needs to be considered when replacing air springs on the rear axle of the Mercedes E class W211/S211 with or without Airmatic DC!

Always replace BILSTEIN air springs in pairs (per axle).

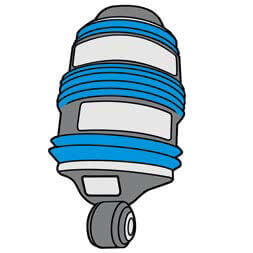

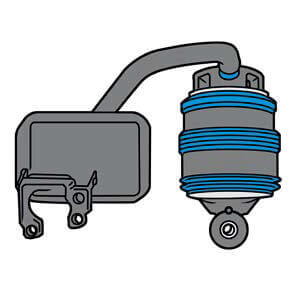

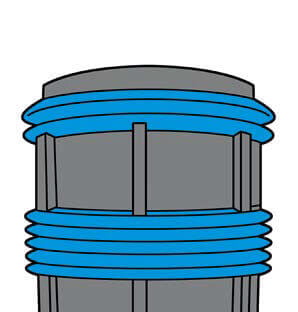

Check the association of the new air springs prior to installation. They must be neither kinked nor twisted. The protective collar must not show any signs of damage and the folds must be formed correctly. Measure the length between the upper support surface and middle of the lower lug. The measurement must not exceed 300 mm. Semi-active air springs (with auxiliary tanks) must not be separated from the connecting hose.

If one of the points is not fulfilled, the air spring will be defective and must not be installed.

Use a suitable diagnostic device. The vehicle manufacturer’s specifications include step-by-step bleeding and filling of the air springs, which must be complied with.

Never lower the vehicle entirely from the lifting platform with unpressurized air springs. Heed the stipulated specifications regarding tightening torque of the pressure line.

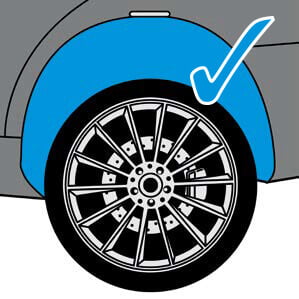

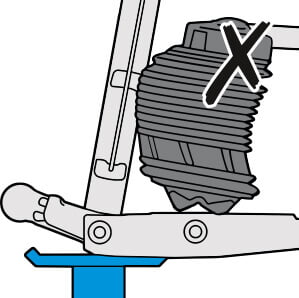

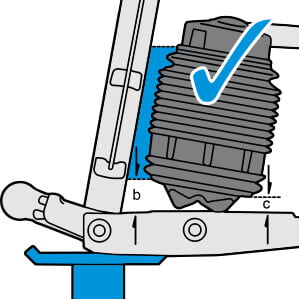

Alignment of the new BILSTEIN air springs must occur in the construction state (K0-position). Use the provided assembly aid for this. You must check for correct installation: the air spring must be parallel to the shock absorber. A distorted installation or an incorrect alignment of the air springs can cause damage to the vehicle or to the air spring. This will lead to air spring failure. Heed the vehicle manufacturer’s specifications regarding the tightening torque and the replacement of nuts and screws.

The protective collar folds must be correctly formed. If necessary, correct by hand. The protective collar must also be free-moving and it must be possible to raise it from the air bellows when filling.

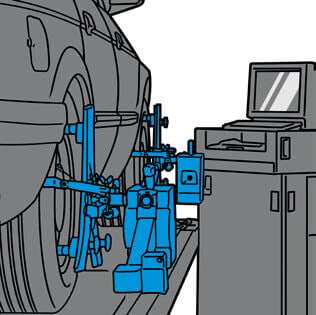

Always align the axles after working on suspension parts.