Avoiding mistakes when installing shock absorbers — these installation tips will help!

Mistakes in the workshop are annoying. In the best case, they only disrupt the processes in the workshop. As a rule, however, they cost money. Quite often, they also annoy customers. In shock absorber and suspension service, however, mistakes can be avoided.

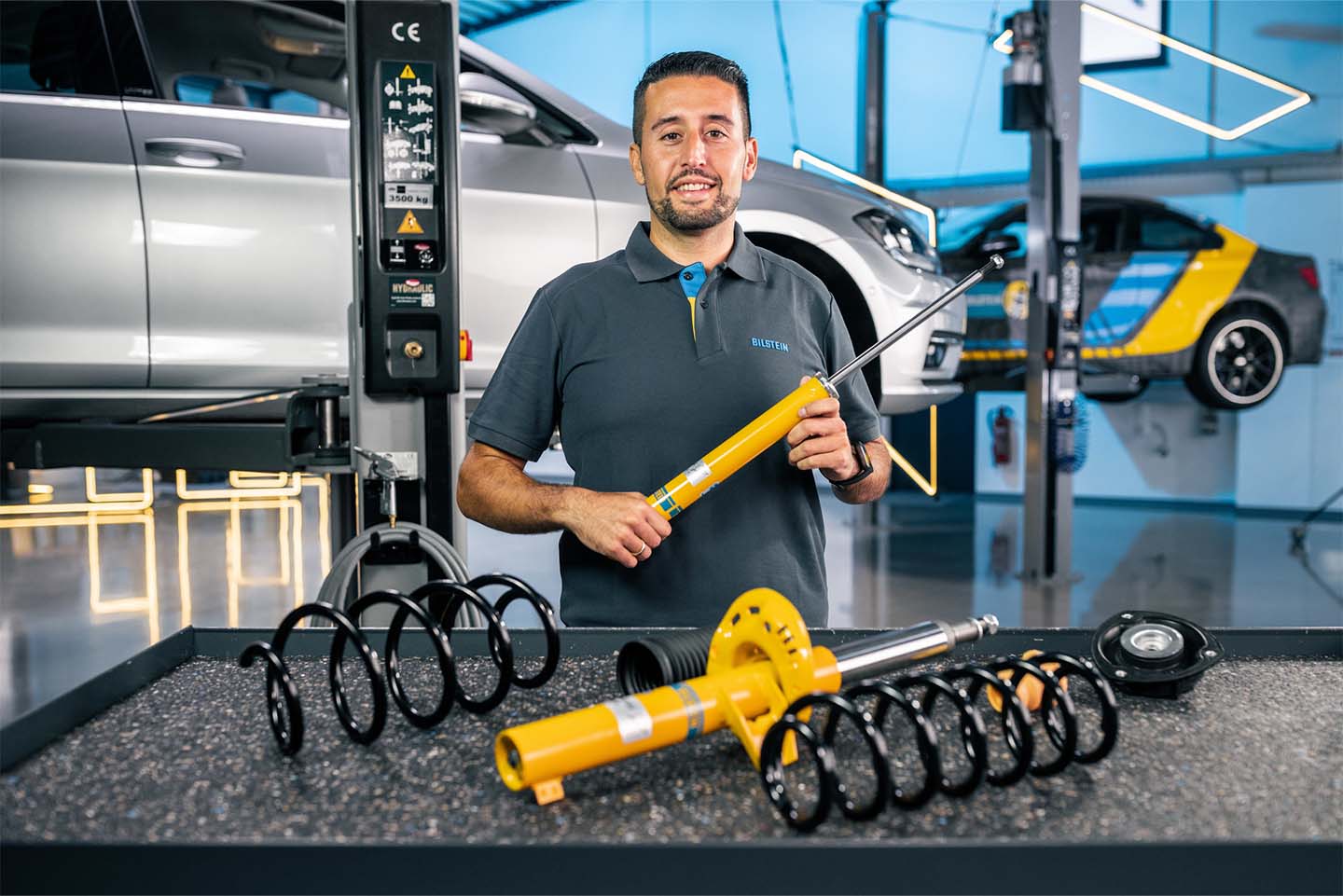

When it comes to problems with the installation of springs and shock absorbers, the shock absorber experts at the BILSTEIN Academy are repeatedly confronted with very similar questions. In the latest video, Rainer Popiol, head of BILSTEIN ACADEMY, and Mustafa Yavuz, who is responsible for technical support for workshops at BILSTEIN Technical Support, clearly point out what really matters.

Workshop Tip #2: Avoiding mistakes when installing shock absorbers — these installation tips will help!

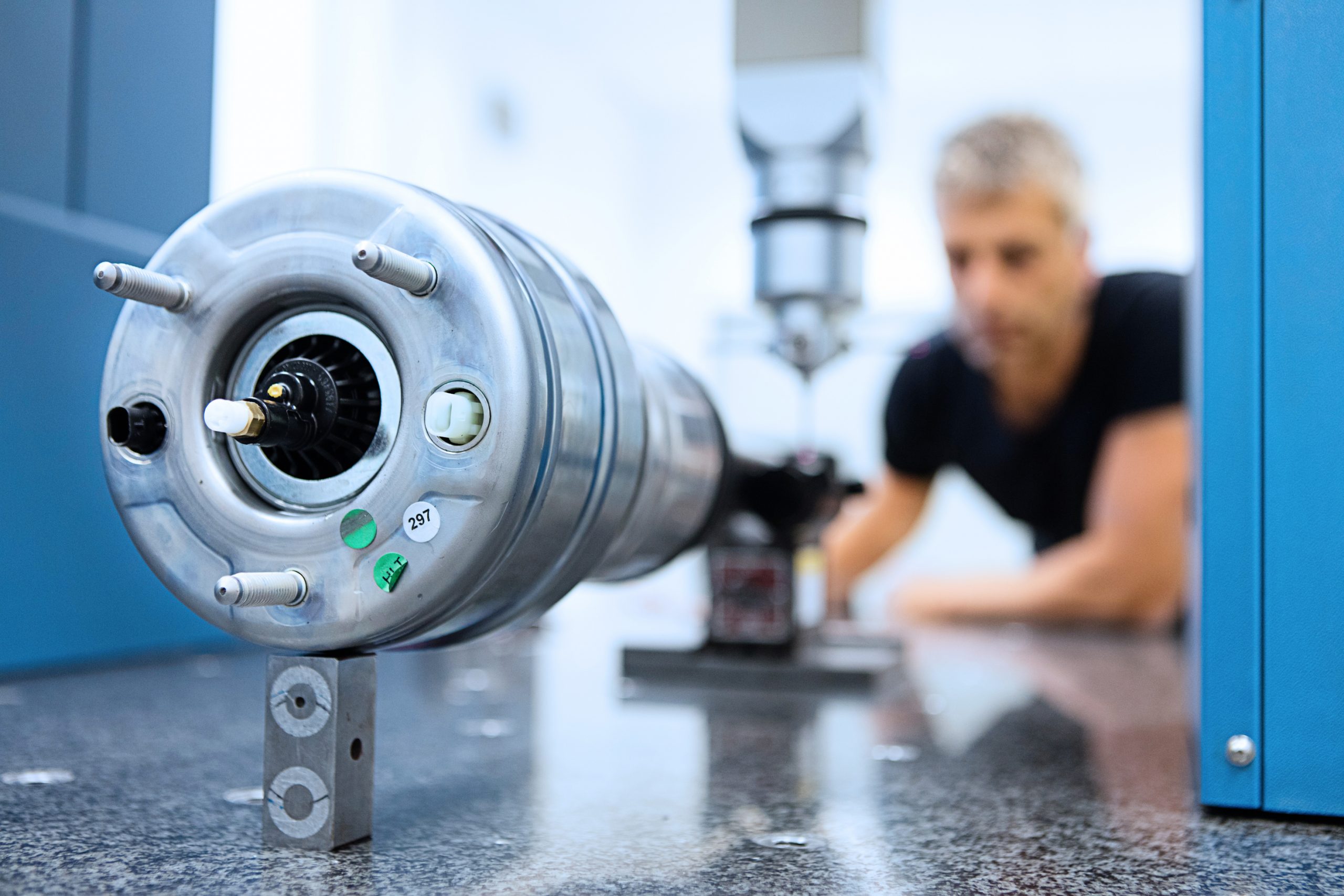

A test drive and a visual inspection on the lifting platform are always part of the compulsory programme in the event of suspension problems. After all, the test drive is an important tool for detecting damage and wear. Most damage can be quickly identified by the visual inspection at the latest. Just as with a very special demonstration object from the BILSTEIN Academy.

“We used to have a lot of shock absorbers to show all the possible damage. Now, we only have one”, reveals Rainer Popiol, “we took it out of a car years ago and there are so many faults on it that we don’t need any others.” This particularly stressed shock absorber also shows that most faults are absolutely avoidable.

Big problem: wrong tools

Such as errors due to the use of the wrong tool. “One problem, for example, is elongated threads on the piston rod”, reports Rainer Popiol. “This is a typical case when using an impact wrench.” Then too much torque is applied to the thread, which can cause it to become elongated.

Popiol warns of another problem: “This can also lead to the piston rod starting to rotate. In the actual shock absorber, the working piston is fixed to the piston rod with a nut. In the worst case, this can loosen or also tighten too much. Both is bad because the seal is damaged.“

The use of gripping pliers or water pump pliers when tightening the shock absorber is also strongly discouraged. This can also damage the piston rod. It is not uncommon for the piston rod to be damaged as well if the shock absorber is driven without a protective tube. This can happen, for example, if the bumpers and protective tube are too old and have come loose from the support bearing.

Suspension and shock absorber knowledge for independent workshops and automotive professionals, presented in a practical and entertaining way: Our experts from the BILSTEIN Academy will provide you with valuable tips and concrete assistance.

Discover all workshop tipsThe problem: Damage to the piston rod can lead to a loss of oil when it passes through the damper’s closure package. In this case, too, the shock absorber must be replaced with a new one.

Small mistakes, big effect

Serious damage to the shock absorber can also occur if it is clamped in a vice. “This squeezing can damage the raceway of the working piston”, knows Rainer Popiol. In addition, new shock absorbers must be installed tension-free, i.e. with the wheels in a compressed state. The vehicle must therefore stand with the wheels on the ground. The wheel alignment stand is well suited for this purpose.

The shock absorber experts at the BILSTEIN Academy always recommend a suspnsion workstation with suitable tools for dismantling and fitting the shock absorbers.

Rainer Popiol: “As a conclusion, we can state: Sometimes a small mistake can have a big effect. In the BILSTEIN Academy, we provide practical information in training courses so that such mistakes cannot happen.”

If you have any questions on the subject of shock absorbers and suspension in the workshop and in the trade, the Technical Support of the BILSTEIN Academy is always ready to help!

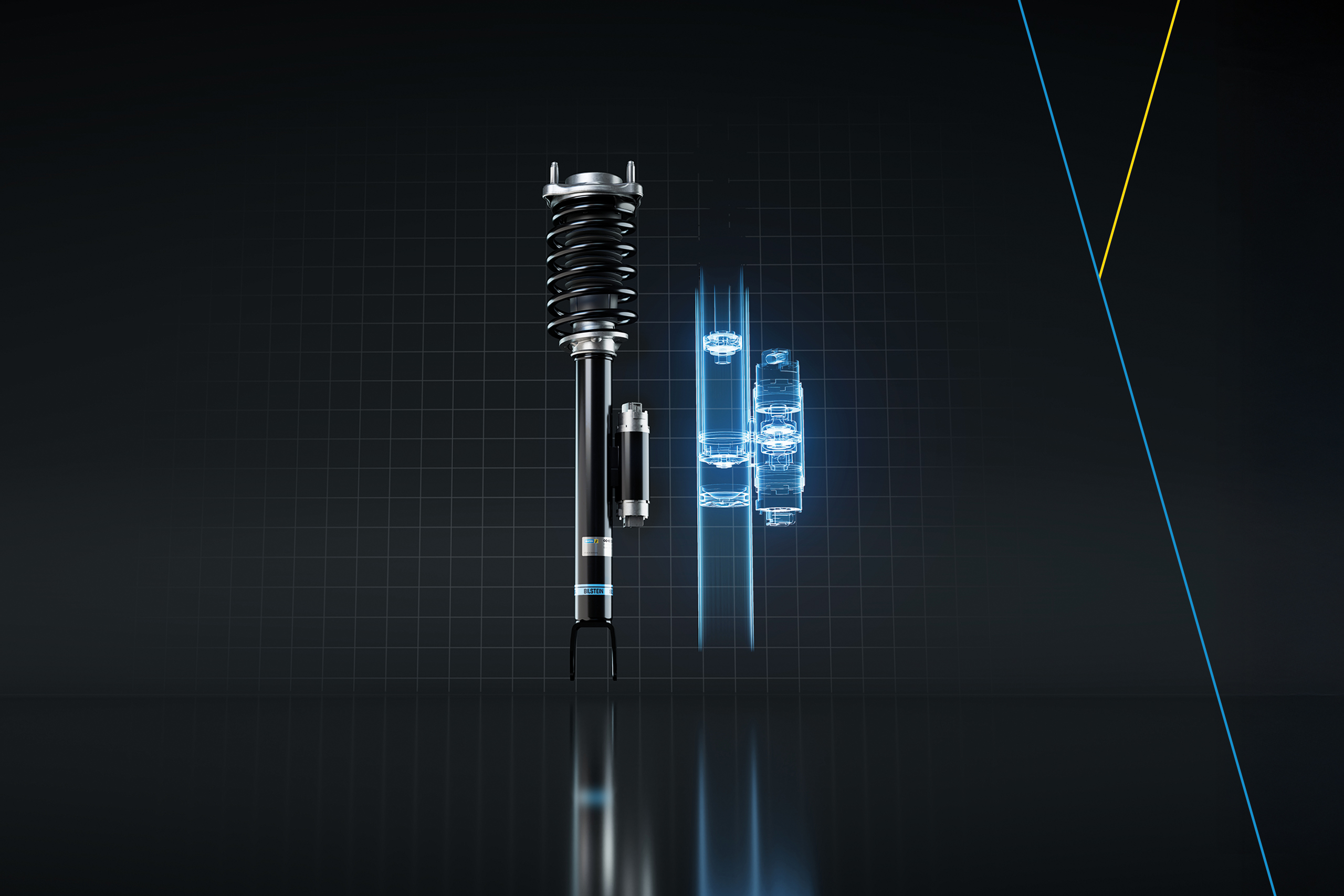

To the BILSTEIN AcademyOur cutting-edge valve technologies and damping systems – from active to passive – guarantee unrivaled top performance and reliability. We bring premium OE quality to the aftermarket, making testing easier and ensuring your success every day.

Discover the technology