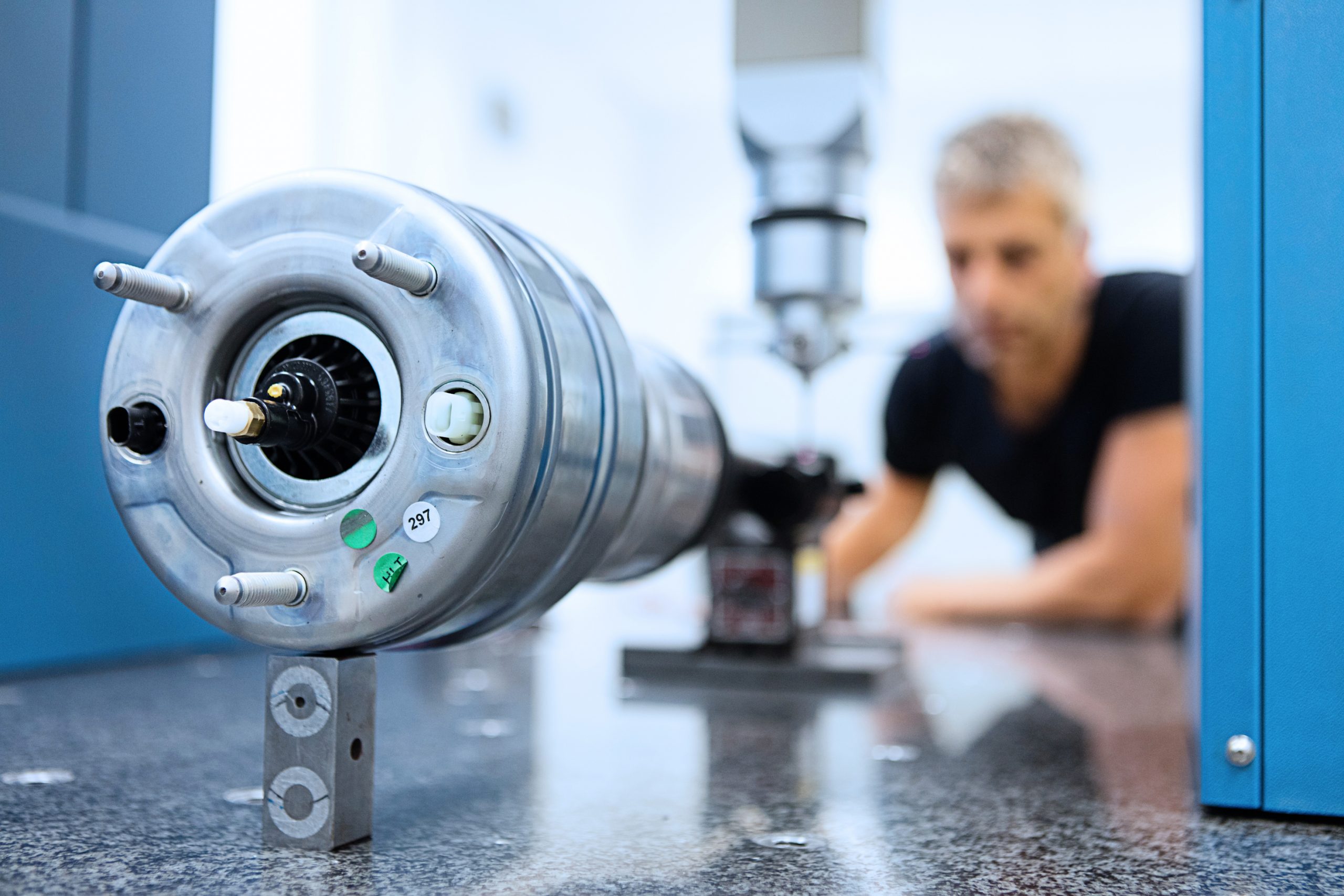

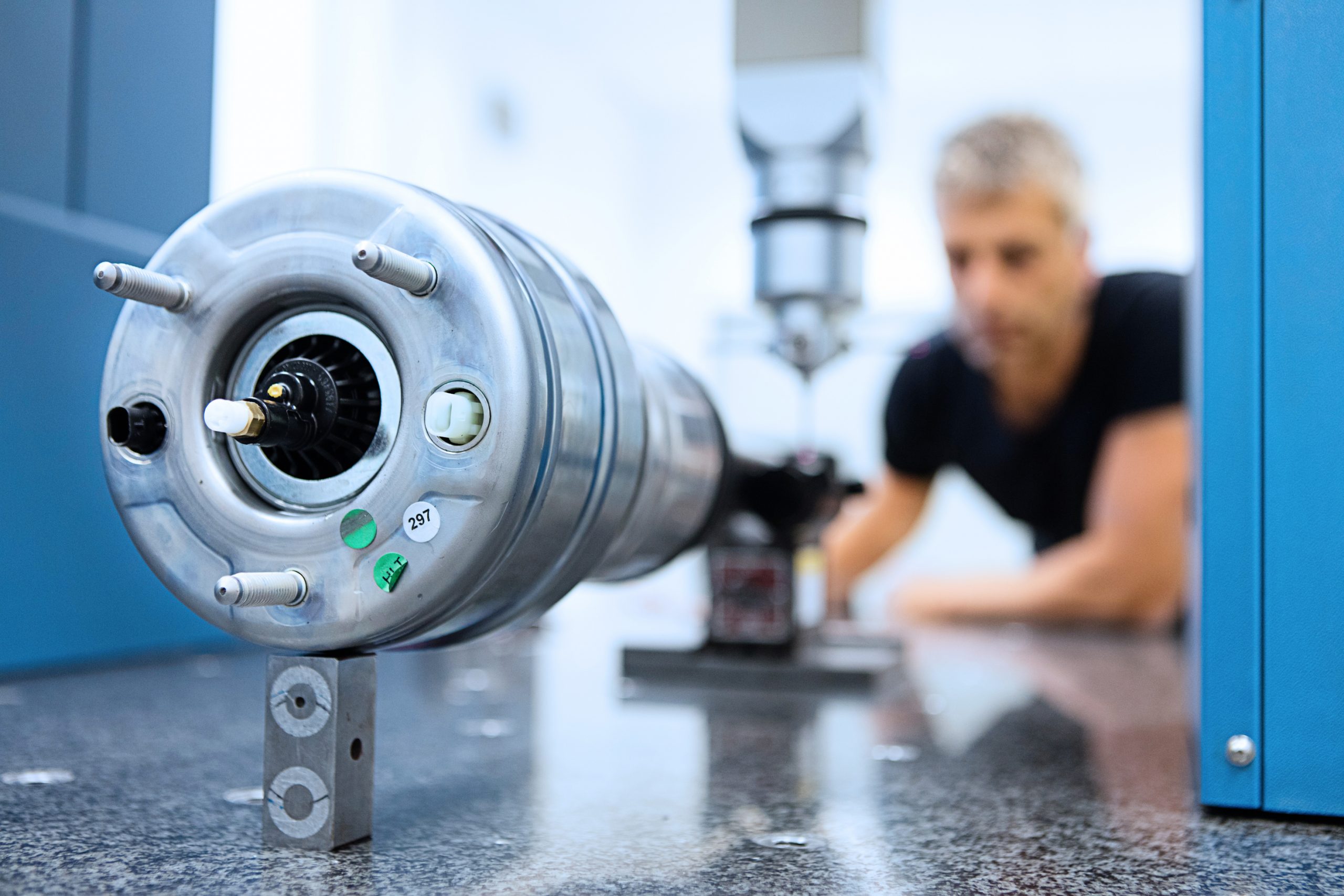

Air spring leaking after installation? How to avoid mistakes during air suspension repair

Ensure correct assembly and tightening torques!

Time and again, our experts at the BILSTEIN Academy are confronted with questions about the correct repair of air suspension systems. From time to time after installation it is not uncommon for the air suspension modules to be leaking and irreparably damaged. Usually, this is due to errors during the repair. If air suspensions do not appear to be completely tight after a repair or are apparently quite leaky, this can have very simple reasons. – Defective spare parts are rather rare. But it is often enough if the specified tightening torques have not been observed. These are often absolutely avoidable problems. With this guide, we provide car professionals with valuable tips to make mistakes in the installation of air springs and air suspensions a thing of the past.

Replacing air springs or air spring modules is neither rocket science nor a mystery. Nevertheless, there is a small checklist for workshops to follow to ensure that no mistakes are made during repair/assembly. It should be at the top of the list: Never lower an air-suspended vehicle to the ground with the lifting platform while the system is still depressurised. Failure to do so could cause irreparable damage to air springs or air spring modules. However, there are also expensive consequences in other areas. Incorrectly selected tightening torques for example are enough to cause leaks.

„Compressed air connections and residual pressure valves are particularly tricky.“

Rainer Popiol, Head of the BILSTEIN Academy

However, the correct tightening torques should be meticulously observed also for the remaining connections. There are no standard values, but the usual range is between 2 and 5Nm. A torque wrench with this setting range can therefore be selected from the tool trolley before starting repairs. The mechanic can find out the exact values from the vehicle manufacturer’s documentation for each vehicle. Since the specifications can change over the course of time, for example due to technical modifications, it is essential to ensure that the data is up to date.

Avoid mistakes when mounting air springs

To prevent leaks, vehicle manufacturers generally specify very precise torque requirements for all connections on air springs and air spring modules. Under no circumstances should these be undercut, otherwise connections could become loose – or they may not be completely airtight.

Tightening them too much can be just as dangerous, as it can damage seals. Even small leaks can cause expensive consequential costs for air suspension systems – even if they are not noticed during driving. The compressor has to work permanently against a gradual loss of pressure and thus wears out more quickly. By the way: Replacements for defective OE compressors are available from BILSTEIN‘s B1 programme.

Photos: Copyright BILSTEIN 2022. Reproduction free of charge if source is named.